The Significance of Calibration in Optimizing Your Galvanometer Scanner's Efficiency

The Significance of Calibration in Optimizing Your Galvanometer Scanner's Efficiency

Blog Article

The Function of a Galvanometer Scanner in Improving Information Purchase Effectiveness

Galvanometer scanners serve as essential elements in the world of data acquisition, particularly due to their capacity to achieve fast and precise positioning of reflective elements. The implications of their integration extend beyond mere effectiveness; they welcome a closer examination of their functional mechanisms and the future innovations that may additionally change information procurement techniques.

Comprehending Galvanometer Scanners

Using accurate electromagnetic concepts, galvanometer scanners offer as essential devices in information procurement systems, enabling the accurate measurement and recording of electric signals. These devices are created to transform electric signals right into mechanical movement, which can then be pictured or taped. The fundamental attribute of a galvanometer scanner is its capacity to react to variants in current, permitting it to identify minute changes in electric signals with high sensitivity.

Galvanometer scanners are critical in a variety of applications, including biomedical study, optical scanning, and top quality control processes in production. Their capability to supply reputable and rapid readings makes them appropriate for settings that require high accuracy and fast feedback times. Furthermore, the building of galvanometer scanners typically consists of a lightweight coil put on hold in an electromagnetic field, allowing them to accomplish high angular deflection with minimal inertia.

The versatility of galvanometer scanners permits integration right into various information purchase systems, improving the total performance of signal measurement. By guaranteeing instantaneous and exact readings, these tools significantly add to the dependability of information analysis, which is essential in both clinical research and commercial applications.

System of Procedure

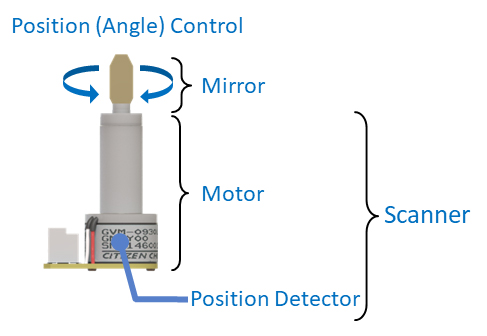

The procedure of a galvanometer scanner depends on the communication in between electric currents and electromagnetic fields to produce mechanical activity (galvanometer scanner). At its core, the gadget contains a coil put on hold within an electromagnetic field. When an electric existing go through the coil, it produces a magnetic field that connects with the exterior electromagnetic field, causing torque that triggers the coil to turn. This rotation is commonly determined in levels, enabling for precise angular variation.

The input current's variation straight affects the angle of deflection, allowing the scanner to react precisely to modifications in the input signal. By manipulating the current's intensity and direction, the galvanometer scanner can accomplish exact and rapid positioning of a reflective component, such as a mirror. This ability is crucial in applications calling for specific placement and scanning, as it promotes the controlled movement of other signals or light beam of lights.

The feedback mechanism included within several galvanometer scanners further enhances their accuracy. Sensors check the placement of the coil, offering real-time data that can be made use of to change the present dynamically. This closed-loop control system ensures that the scanner preserves precision throughout its operational range.

Applications in Numerous Industries

Galvanometer scanners discover considerable applications throughout different markets as a result of their precision and quick feedback abilities. In the field of telecoms, they are essential to laser light beam guiding for optical networking, enabling high-speed data transmission. Medical diagnostics also benefit substantially from galvanometer scanners, as they are used in laser-based imaging systems, such as Optical Comprehensibility Tomography (OCT), supplying high-resolution photos for better diagnosis.

Furthermore, in clinical study, galvanometer scanners are necessary for laser scanning microscopy, allowing researchers to catch detailed pictures of biological specimens and products. They are also used in width for high-precision dimensions, making sure compliance with stringent sector standards. In general, the flexibility and effectiveness of galvanometer scanners make them vital across diverse markets, dramatically adding to innovations in modern technology and quality control.

Benefits for Information Purchase

In data purchase procedures, the incorporation of galvanometer scanners substantially enhances measurement precision and speed. These tools make use of high-precision mirrors and rapid angular activities to direct laser beam of lights or source of lights with remarkable accuracy, which is crucial for applications needing specific positioning and timing.

The adaptability of galvanometer scanners permits seamless integration right into numerous data procurement systems, adapting to specific demands in areas such as biomedical imaging, materials screening, and environmental tracking. This versatility not just enhances the versatility of the tools yet additionally maximizes the total effectiveness of data collection workflows.

In addition, the small layout of galvanometer scanners promotes simple installation and maintenance, more adding to functional effectiveness. Ultimately, the benefits of using galvanometer scanners in information acquisition refines convert to far better top quality information, lowered operational prices, and boosted task turn-around times.

Future Trends and Innovations

Innovations in modern technology are positioned to drive the advancement of galvanometer scanners, additionally boosting their function in information procurement. Emerging technologies are most likely to concentrate on increasing scanning rates and enhancing precision, enabling a lot more efficient information collection in applications ranging from biomedical imaging to commercial automation.

Integration of fabricated intelligence and artificial intelligence algorithms is expected to play a critical duty in maximizing scanner efficiency. These modern technologies can make it possible for real-time adjustments during the scanning process, enhancing accuracy and minimizing errors. The unification of advanced products, such as lightweight composites, can lead to the growth of even more agile scanners with improved responsiveness.

Additionally, the fad towards miniaturization will likely result in small galvanometer systems, making them much more obtainable for various applications, including portable tools. Enhanced connectivity through IoT integration can promote smooth data transfer and remote tracking, additional enhancing information acquisition procedures.

As the need for high-resolution imaging and quick information handling remains to expand, galvanometer scanners will certainly get redirected here evolve to fulfill these needs, positioning themselves as crucial tools in the pursuit for efficiency throughout multiple fields. The future promises a transformative trip for galvanometer innovation, driven by innovation and precision.

Final Thought

In final thought, galvanometer scanners considerably boost information procurement performance through their specific and fast positioning capacities. As industries proceed to incorporate these scanners right into their systems, recurring developments and patterns are anticipated to further enhance their efficiency, solidifying their important role in the evolution of data acquisition innovations.

Galvanometer scanners serve as crucial elements in the world of information acquisition, specifically due to their capability to accomplish fast and precise positioning of reflective components.Using precise electromagnetic principles, galvanometer scanners serve as important devices in data procurement systems, making it possible for the precise measurement and recording of electrical signals. In general, the adaptability and efficiency of galvanometer scanners make them indispensable across diverse markets, substantially adding to wikipedia reference advancements in modern technology and quality guarantee.

One of the key advantages of galvanometer scanners is their capability to achieve high-speed data collection.In final thought, galvanometer scanners considerably enhance data purchase effectiveness through their rapid and precise positioning abilities.

Report this page